Product Categories

Hot Products

Application Of Rubber Lined Carbon Steel Pipes In Mining Slurry Transportation

Release time:

2025-02-28

Due to the special properties of mining mud, the pipeline for transporting mining mud must meet the following points:

1: Mud usually contains solid particles, such as quartz sand, which will cause wear on the inner wall of the pipeline, so the pipeline material must have good wear resistance.

2: Mining mud may be corrosive such as acidity and alkalinity. For example, some copper mine mud is acidic, which requires the pipeline material to be corrosion-resistant.

3: Considering the complex terrain of the mine, the pipeline may need to adapt to certain terrain changes and vibrations, so the material should have a certain flexibility.

4: During the mud transportation process, pressure fluctuations may occur due to the start and stop of the pump, the opening and closing of the valve, etc. The pipeline and its accessories should be able to withstand certain pressure fluctuations without problems such as rupture or leakage.

Rubber-lined carbon steel pipelines can meet the needs of mining mud transportation.

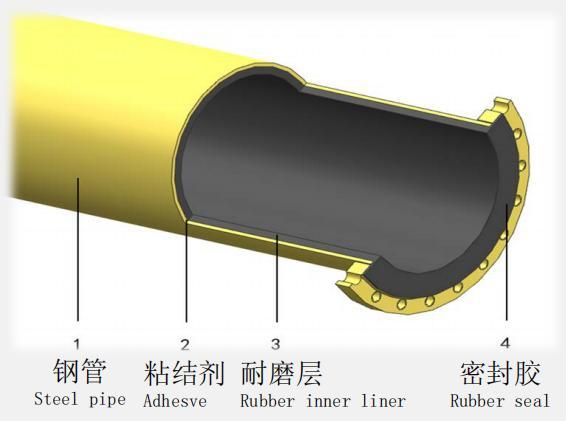

Rubber lined carbon steel pipe is a composite pipe with carbon steel as the outer pipe skeleton and wear-resistant, corrosion-resistant and high-temperature resistant rubber as the inner lining layer.

Jiaozuo Debang Technology Co., Ltd. can provide customers with mining mud transportation pipelines and can provide pipes with sizes of DN50-DN2000.

The pipes provided meet the following standards:

《GB Chinese Pipeline Standard》

《ASME American Pipeline Standard》

《GOST Russian Pipeline Standar》

《DIN European Pipeline Standard》

《ANSI American Pipeline Standard》

《SABS African Pipeline Standard》

Key words:

Related News

Nov 20,2025

Ceramic Liners: Grain Handling Customized Wear Liners

May 30,2025

How To Select Ceramic Lined Pipes

May 20,2025

Selection of Corrosion-resistant Linings for Hydrochloric Acid Plants