Product Categories

Hot Products

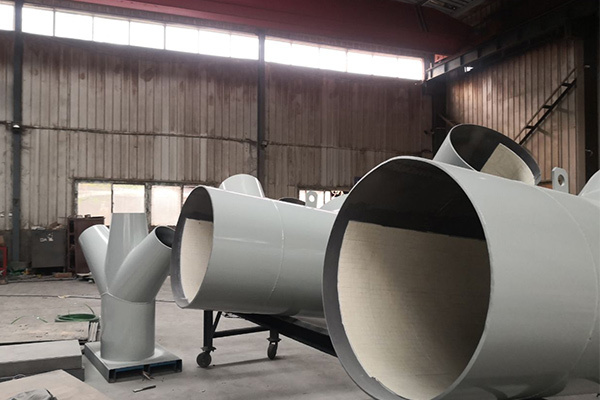

Dust Removal Pipe Ceramic Lining Project: Solving The Wear Resistance Problem of Dust Removal Pipes

Release time:

2025-04-24

The choice of dust collection duct is often related to the particle size of the dust and the velocity of the dust.

Ducts with larger diameters and lower flow rates generally have less wear because the dust particles have more room to spread. High-speed systems tend to have higher wear rates. Adjusting the duct design to balance the flow rate and duct size can reduce wear.

In order to meet the wear-resistant needs of customers' large-sized dust removal pipes, we provide customers with wear-resistant alumina ceramic linings. The wear resistance of alumina is more than 200 times that of carbon steel. The Rockwell hardness of alumina is above HRA80 and the Mohs hardness reaches level 9, which is second only to diamond.

In order to save costs for customers, we provide customers with a wear-resistant solution of partially bonded alumina ceramics, which only provides ceramic wear resistance in the direction of dust flow and friction impact.

Key words:

Related News

Nov 20,2025

Ceramic Liners: Grain Handling Customized Wear Liners

May 30,2025

How To Select Ceramic Lined Pipes

May 20,2025

Selection of Corrosion-resistant Linings for Hydrochloric Acid Plants