Product Categories

Hot Products

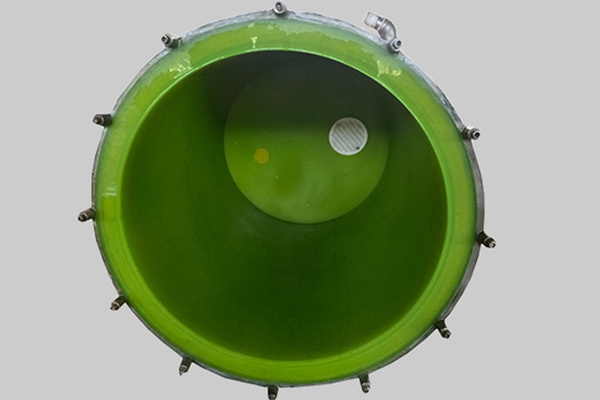

Application Of Polyurethane Ball Mill

Release time:

2025-03-17

In the field of industrial fine grinding, ball mills have always been the most widely used and frequently used industrial equipment.

Since the use of ball mills needs to be continuous, the wear problem of ball mills has always been the main problem that manufacturers need to face.

Our company provides customers with design solutions and construction of ball mill linings.

Some common materials using polyurethane ball mill linings:

Such as iron ore, copper ore, lead-zinc ore, etc. These ores have high hardness and wear the linings more during the ball milling process. The polyurethane ball mill lining can effectively resist the impact and friction of the ore with its excellent wear resistance, extend the service life of the lining, and also reduce noise and energy consumption.

Such as quartz, feldspar, calcite, kaolin, etc. Non-metallic ores have different properties, some of which are corrosive or sticky. The corrosion resistance and good material fluidity of polyurethane linings make them suitable for the processing of these ores, which can prevent materials from adhering to the linings and ensure the ball milling effect.

Chemical raw materials such as calcium carbonate, barium carbonate, titanium dioxide, etc. need to be finely ground during the production process. Polyurethane lining can provide a stable grinding environment, avoid impurities from mixing into the materials, ensure the purity and quality of chemical raw materials, and its good wear resistance can also meet the requirements for long-term stable operation of equipment in chemical production.

Including cement, gypsum, ceramic raw materials, etc. In the production of building materials, ball mills are used to grind raw materials to a suitable particle size. Polyurethane linings can adapt to the characteristics of these materials, reduce equipment wear and maintenance costs, improve production efficiency, and help reduce dust emissions and improve the production environment.

Polyurethane ball mill linings can also be used for ball milling of refractory raw materials such as corundum, magnesia, and sillimanite. Refractory materials are usually hard and brittle. The elasticity and wear resistance of polyurethane linings can better protect equipment during the grinding process, while reducing pollution to materials and ensuring the quality of refractory materials.

Key words:

Related News

Nov 20,2025

Ceramic Liners: Grain Handling Customized Wear Liners

May 30,2025

How To Select Ceramic Lined Pipes

May 20,2025

Selection of Corrosion-resistant Linings for Hydrochloric Acid Plants